The Garage Makeover Blog by Slide-Lok

DIY Epoxy Garage Floor Coating Repaired by Professionals in Casper, WY

12/11/2018

Grinding removes the failed epoxy coating and profiles the concrete similar to 60 grit sandpaper, which is needed for the next coating to soak into the concrete to prevent adhesion failure.

Grinding removes the failed epoxy coating and profiles the concrete similar to 60 grit sandpaper, which is needed for the next coating to soak into the concrete to prevent adhesion failure.

The homeowners saved initially by installing this garage floor coating themselves. After it started to fail they called us to fix it.

The homeowners saved initially by installing this garage floor coating themselves. After it started to fail they called us to fix it.

This store bought DIY epoxy flooring kit was installed by the homeowners. They were less than pleased when it began to peel and have hot tire pickup issues.

This store bought DIY epoxy flooring kit was installed by the homeowners. They were less than pleased when it began to peel and have hot tire pickup issues.

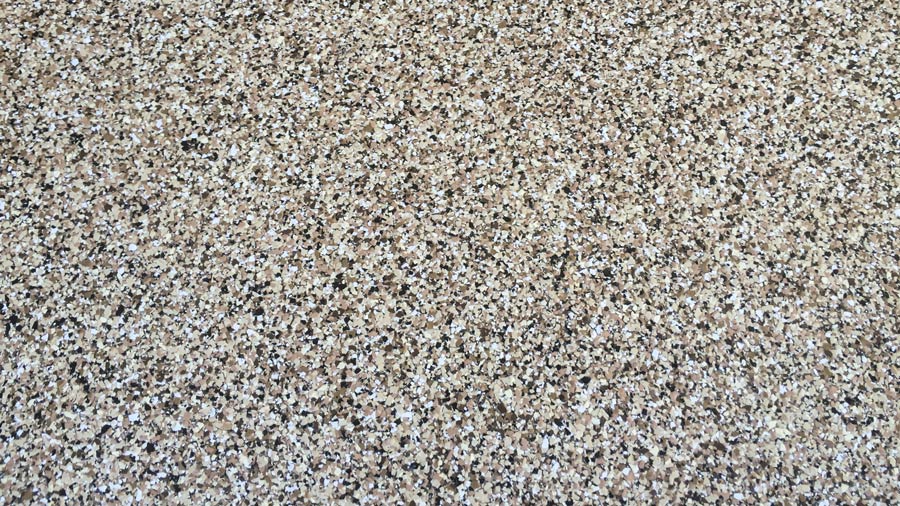

And this is the new Saddle Tan Polyaspartic Garage Floor Coating our Casper, Wyoming, team installed.

And this is the new Saddle Tan Polyaspartic Garage Floor Coating our Casper, Wyoming, team installed.

Wow! In less than 1 day the DIY epoxy was removed and this new polyaspartic garage floor coating was installed.

Wow! In less than 1 day the DIY epoxy was removed and this new polyaspartic garage floor coating was installed.

Another angle of the new polyaspartic garage floor.

Another angle of the new polyaspartic garage floor.

DIY Epoxy Removed & Replaced with Polyaspartic in 1 Day!

As winter temperatures arrive across the US and Canada, Slide-Lok dealers are able to stay busy and install garage floor coatings thanks to the wide degree of working temperatures of our polyaspartic coatings. Our polyaspartic garage floor coating can be applied well below freezing temperatures, whereas standard epoxy coatings are not suited for weather below 50 degrees! Just last week our local, Slide-Lok of Casper, dealer was able to heed this homeowners call for help. The homeowners had applied a DIY epoxy garage floor kit from one of the large home improvement stores and were experiencing epoxy coating failure. In less than 8 hours the local dealer removed the failing epoxy coating, profiled the concrete similar to 60 grit sandpaper and applied a Slide-Lok polyaspartic garage floor coating.

The above garage is located in Casper, WY, and is one example of a homeowner that tried their hand at using a DIY epoxy garage floor painting kit. They installed it this past summer and followed the instructions to a "T". They were excited that it turned out as good as it did for costing so little and being relatively easy to apply, but those were the only praises they sang for the DIY kit and that praise was short lived. Within months the floor had started to peel, crack, chip, bubble, and experience hot tire pickup issues. They searched the web for ways to fix their epoxy garage floor. Faced with painting over the issues and praying they didn't come back, or renting the proper industrial equipment to grind off the epoxy and try again, they chose to call our local dealer to fix it the right way.

So, Why Do DIY Garage Floor Epoxy Paint Kits Get A Bad Rap?

If you've ever walked down the paint aisle at your local home improvement store you've probably seen the DIY Garage Floor Epoxy Painting Kits for $50-100. If you ask anyone that's used these products you're sure to get alot of different answers. That's because many people don't have a good long term experience with these low cost / cheap products. They often complain of the epoxy paint bubbling or peeling up fairly quickly. There are even a couple of stellar reviews that make you think; just maybe these products don't deserve the bad rap they get.

These kits are of course cheap, and appeal to the DIY weekend warriors that are looking for a relatively quick and easy project. I'm a car guy myself and I love tackling small car and home improvement projects on the weekend. The allure of these kits is perhaps the extremely low cost and the extremely high expectations most people have due to the pictures and advertising of these products. Where these products typically fall short is comparing them to high solids, high performance coatings, and the lack of training and communication needed to install a garage floor coating correctly. And of course, the big, big difference, that spells disaster in many of these cases is the floor preparation method used.

High Performance Floor Coatings & Proper Flooring Preparation

Many of these DIY garage floor kits just can't compete performance wise with the high end coatings. That's because to meet the extremely low price point consumers expect at the big box stores these products have to be altered. What you get at your local home improvement store is not the same chemical a flooring contractor would get from a specialty coatings manufacturer or supply house. These DIY kits are often low solids and water based technology; combined they create a very inexpensive low cost flooring system. There's nothing wrong with these products if you know your intended application and have realistic expectations for how long a low solids thin build coating should last compared to a high solid thick film build coating a professional might install.

Professional flooring contractors often use specialty coatings and equipment that just isn't as easily accessible to the typical DIY weekend warrior. High performance coatings are often high solids coatings that feature excellent chemical resistance, adhesion, and abrasion characteristics. Adhesion being one of the most important factors in flooring failures is why the professionals choose to shot blast or diamond grind concrete. The DIY kits usually call for a light degreasing/washing of your floor or an acid etching protocol. It is the acid etching and ammonia neutralization that causes a lot of extra problems, as DIY’ers often do not completely neutralize these solutions, either leaving their floor acidic or alkaline, and not pH neutral, which is critical to long life and proper adhesion. We do not recommend acid etching protocols because they have a higher rate of failure compared to shot blasting and better yet, diamond grinding your concrete.

We've written about acid etching before so I'll try to keep this short. Acid etching is the cheap man's floor prep compared to shot blasting or diamond grinding. Acids are used for etching and cleaning the concrete of stains and other residue from years of use; it does actually work. The downfalls of acid is that you have to properly neutralize it. This involves an ammonia neutralizing wash and then plenty of water to rinse out the neutralized components. Many people fail to realize just how important this step is and either fail to neutralize the acid or completely wash it out of the floor. Even if you do your best, remember that concrete is porous. So, no matter how hard you try it is impossible to get it all out. That's why so many acid etched floors bubble and peel later on, because unneutralized acid eventually rises to the surface and starts eating away at the coating from underneath, causing the famous random bubbling patterns seen in so many of these failed DIY big box store garage floors.

What We Think of DIY Garage Floor Kits

We LOVE them! Honestly. They fill a vital segment of the market that introduces many homeowners to the idea they should paint their garage floor. Some homeowners choose to go the DIY route, and some choose a professional over the DIY kit. Many of our dealers wouldn't be as busy as they are if not for all the calls they get to fix floors due to these kinds of inexpensive kits. We aren't saying the kits are bad. They can be very good and cost effective if you have realistic expectations and properly prepare the floor before painting. The key to an excellent long lasting floor coating is the same as a good paint job on your car - PREPARATION. We all know that the $500 bargain Maaco paint job falls incredibly short of a $3,500 professional paint job in terms of quality, that's because the latter includes better paint and more importantly better preparation of the coating surface.

This 3 car garage in Casper, Wyoming, now has the best garage floor coating in the industry backed by a 15 year limited warranty*. You can't beat that!

So what are you waiting for, get your FREE ESTIMATE today: Contact Slide-Lok Garage Interiors.

Local Slide-Lok Authorized Dealer - Slide-Lok of Casper

Call: (307) 797-6657

email: click here to e-mail this local dealer

About The Author

Samuel Strayer is a trained chemist with a Bachelor of Science in Biochemistry from Arizona State University with an emphasis on material and polymer science. Samuel has been involved in developing and testing coating systems for over 10 years.

Keywords: garage, flooring, floor, coatings, polyaspartic, epoxy, diy, kit, failure, concrete, preparation, diamond, grinding, shot, blast, casper, wyoming, wy

© Copyright, 2018, Slide-Lok (DBA), Mirabel Coatings Inc.

Back to Posts on The Garage Makeover Blog

Featured Blog Posts

- Concrete Coating System Adhesion Study

- We Want To Thank Our Suppliers!

- Closed July 2-5 for Independence Day

- Best Garage Floor Coatings in Phoenix, AZ

- New Flooring Chips and Flakes Brochure - Featuring 41 Colors!

- How To Choose The Right Color To Paint Your Garage

- 41 Stock Blends of Color Chips and Flakes for Floor Coatings

- 6 New Color Chips & Flakes for Floor Coatings

- Residential and Commercial Floor Coatings in Phoenix, Arizona

- 13 New Color Chips & Flakes for Floor Coatings

- 4 Home Improvement and Organizational Tips To Elevate Your Home

- Floor Coating Video

- Failed DIY Garage Floor Coating vs. Pro

- How To Get Smoother Top Coats, Chip and Flake Floor Coating Sealer

- Closed Labor Day Weekend Sept. 4-7

- Garage Floor Coating Transformation in Laramie, Wyoming

- Flooring Chips and Flakes Now Available By The Bucket

- Closed July 3-6 For Independence Day

- Fighting Allergies During COVID-19

- Become An Authorized Slide-Lok Floor Coating and Storage Installer

- Inventory Levels and Lead Times - Impacted Supply Chains

- Flooring Chips and Flakes Brochures

- Waterborne Epoxy Garage Floor Coating Training Video

- SBA Paycheck Protection Program - CARES ACT

- Spring Cleaning During Coronavirus Pandemic

- Staying Healthy: How To Minimize Your Risks Of Catching The Coronavirus (COVID-19)

- We Are Open, Taking & Shipping Orders

- When To Paint Your House - 5 Useful Tips For Interior Painting

- 10 Ideas For Your Garage Makeover

- Surviving WOC 2020: Coronavirus (COVID-19)

- The Best Time Of Year To Paint The Exterior Of Your Home

- Two Tone Chip Epoxy Floor in Mesa, Arizona

- Fitness Center Gets Metallic Epoxy Floor Coating

- Western Coating Societies Symposium and Show 2019

- Polyurea Is Better Than Polyaspartic?

- How To Improve Your Home's Curb Appeal

- 2 Tone Garage Floor Coating in Omaha, Nebraska

- Colorado Springs Garage Floor Restoration

- Polyaspartic Coating Survives as Boat Deck Coating

- Best Wasp & Hornet Pesticide Spray From Home Depot 2019

- Polyaspartic Flooring Withstands Flooding in Austin, Texas

- Garage Makeovers Shine in Florida

- Best Garage Remodels in Phoeniz, AZ

- Best Garage Makeovers of South Carolina

- Best Floor Coatings for Auto Mechanic Shops

- Garage Floor Coating Install in Anderson, IN

- DIY Epoxy Coating Repair in Casper, WY

- Polyaspartic Garage Floor Install in Pittsburgh, PA

- Garage Flooring & Painting in Omaha, Nebraska

- Concrete Coating Install in Eagan, Minnesota

- Garage Cabinet Installation in Wyoming, Michigan

- Garage Floor Coatings Albany, IN

Contact Local Dealer

Find a Slide-Lok Garage Floor & Cabinet dealer in your area.

Call: 1-800-835-1759

E-mail: Click to e-mail.

Featured Blog Posts

- Concrete Coating System Adhesion Study

- We Want To Thank Our Suppliers!

- Closed July 2-5 for Independence Day

- Best Garage Floor Coatings in Phoenix, AZ

- New Flooring Chips and Flakes Brochure - Featuring 41 Colors!

- How To Choose The Right Color To Paint Your Garage

- 41 Stock Blends of Color Chips and Flakes for Floor Coatings

- 6 New Color Chips & Flakes for Floor Coatings

- Residential and Commercial Floor Coatings in Phoenix, Arizona

- 13 New Color Chips & Flakes for Floor Coatings

- 4 Home Improvement and Organizational Tips To Elevate Your Home

- Floor Coating Video

- Failed DIY Garage Floor Coating vs. Pro

- How To Get Smoother Top Coats, Chip and Flake Floor Coating Sealer

- Closed Labor Day Weekend Sept. 4-7

- Garage Floor Coating Transformation in Laramie, Wyoming

- Flooring Chips and Flakes Now Available By The Bucket

- Closed July 3-6 For Independence Day

- Fighting Allergies During COVID-19

- Become An Authorized Slide-Lok Floor Coating and Storage Installer

- Inventory Levels and Lead Times - Impacted Supply Chains

- Flooring Chips and Flakes Brochures

- Waterborne Epoxy Garage Floor Coating Training Video

- SBA Paycheck Protection Program - CARES ACT

- Spring Cleaning During Coronavirus Pandemic

- Staying Healthy: How To Minimize Your Risks Of Catching The Coronavirus (COVID-19)

- We Are Open, Taking & Shipping Orders

- When To Paint Your House - 5 Useful Tips For Interior Painting

- 10 Ideas For Your Garage Makeover

- Surviving WOC 2020: Coronavirus (COVID-19)

- The Best Time Of Year To Paint The Exterior Of Your Home

- Two Tone Chip Epoxy Floor in Mesa, Arizona

- Fitness Center Gets Metallic Epoxy Floor Coating

- Western Coating Societies Symposium and Show 2019

- Polyurea Is Better Than Polyaspartic?

- How To Improve Your Home's Curb Appeal

- 2 Tone Garage Floor Coating in Omaha, Nebraska

- Colorado Springs Garage Floor Restoration

- Polyaspartic Coating Survives as Boat Deck Coating

- Best Wasp & Hornet Pesticide Spray From Home Depot 2019

- Polyaspartic Flooring Withstands Flooding in Austin, Texas

- Garage Makeovers Shine in Florida

- Best Garage Remodels in Phoeniz, AZ

- Best Garage Makeovers of South Carolina

- Best Floor Coatings for Auto Mechanic Shops

- Garage Floor Coating Install in Anderson, IN

- DIY Epoxy Coating Repair in Casper, WY

- Polyaspartic Garage Floor Install in Pittsburgh, PA

- Garage Flooring & Painting in Omaha, Nebraska

- Concrete Coating Install in Eagan, Minnesota

- Garage Cabinet Installation in Wyoming, Michigan

- Garage Floor Coatings Albany, IN

Contact Local Dealer

Find a Slide-Lok Garage Floor & Cabinet dealer in your area.

Call: 1-800-835-1759

E-mail: Click to e-mail.