The Home Improvement Blog by Slide-Lok Garage Interiors

Waterborne Epoxy Garage Floor Coating Install & Training in Buckeye, AZ

Modern waterborne epoxy coatings are affordable, easy to work with, and offer increased protection and durability.

4/17/2020

Water Based Epoxy Garage Floor Coatings

Floor coatings are a great investment for protecting your garage’s concrete from stains, leaks and rust. Concrete is a very porous solid and will soak up liquids like oil, brake fluid, transmission fluids and more making your garage floor difficult to clean and maintain. With a garage floor coating like epoxy, polyurethane or polyaspartic your garage floors will be easier to clean and can complement your garage’s aesthetic. At Slide-Lok there are so many colors to choose from as well as metallics and chips to add, making your garage a beautiful unique space in your home.

Waterborne epoxy floor coatings are a great idea for homeowners who don’t want to spend a whole lot, but want the same beautiful glossy and durable floor finish. Our “how to” below gives you an idea of how easily your floors can be transformed in a weekend. We recently applied a waterborne epoxy garage floor to a Phoenix area home. Watch how the floor coating totally transforms the space of a new spec home from plain and simple to durable and vibrant.

Garage Floor Coating Training in Arizona

In March of 2019 our team travelled to Buckeye, Arizona, to coat a garage floor using our new waterborne epoxy coatings. This floor doubled as a video and training event for local installers to see our new waterborne epoxy coatings in action. The floor has now been down for over a year with zero complaints and looks as good as it did when we finished on March 17, 2019.

Waterborne Epoxy Garage Floor Training Video

Watch the video for yourself. See our new waterborne epoxy coatings in action.

Flooring Preparation

It is important to prep the concrete before applying epoxy, or any coating for that matter. This allows better adhesion and a longer lasting floor. There are many flooring prep methods available, for homeowners and novice floor installers pressure washing and acid etching are the lowest barriers to entry. If you have the time and money we always advise you to diamond grind or shot blast your floor to ensure the concrete surface is prepared as best as possible. Diamond grinding and shot blasting prepare the surface in a way that acid etching cannot, ensuring a surface that the coating can penetrate and bite into guaranteeing excellent adhesion and longevity for your floor coating.

Pressure Washing & Acid Etching

To begin, you want to hook up a pressure washer to a hose and rinse the surface concentrating on cracks and corners. Next, you want to sweep any debris or dirt out of cracks and work back to front. Once the surface is rinsed, pinpoint any stains such as oil and tire marks. Leaving these be can affect the adhesion of the floor coating. Simply use a cleaner and degreaser to get rid of these blemishes. To make the solution, pour the concentration plus water to a buffer. Buff out the entire garage, concentrating on the areas that were the dirtiest. After the entire surface is buffed, rinse the surface with water from back to front. Once rinsed, sweep out additional water or squeegee it.

Now, it’s time to acid etch the concrete. In a multi-purpose container, add 1 part acid and 4 parts water. Stir the solution with a paint stick making sure it is fully mixed. Pour the solution in various areas. Using a broom, coat the floor evenly with the solution for about 10 minutes.

After you are done, you are going to neutralize the floor with ammonia and rinse with water. In a new multi-purpose container, mix 1 part ammonia with 7 parts water. Mix thoroughly with a new paint stick. Brush the neutralizing solution evenly throughout the garage. Brush the solution in rows and in circles to make sure you are neutralizing the acid. Finally, rinse the floor from back to front making sure all the solution is rinsed away. To dry the concrete, blow dry the surface.

You want to let the floor dry for about 20-30 minutes. Our proprietary waterborne epoxy coatings can be applied when the concrete is damp, but the concrete cannot be wet or cannot have pooling water on the surface. To test if your concrete is ready, place your finger on the surface of the concrete. If there is water on your finger after touching the concrete, it is still too wet.

Flooring Primer Coat

Before pouring materials out of the buckets, thoroughly mix A & B components separately with their own clean paint stick. Now you are going to prepare Epoxy 150 in a multi-purpose container. Mix 2 parts of A and 1 part of B. Add 6 ounces of pigment per gallon of solution and 1 part water. Mix the solution for 2-3 minutes.

With the solution, you are going to carefully cut in all edges and cross joints. Concentrate on areas along the trim or wall, any vertical areas and cracks. When done, you are going to pour the primer on the floor and roll it out evenly. Let the prime coat soak in for 1-2 hours.

Broadcast Chip Coat

When the primer coat has been allowed to soak in for 2 hours, it will still be tacky (sticky) so you'll need spiked shoes for the this part. Otherwise, wait 12-24 hours before beginning the next coat.

Mix buckets A and B separately with individual paint sticks. Prepare Epoxy 250 in a larger container or bucket. Mix 2 parts of A and 1 part of B with a drill. Add 2-3 parts of water to get desired consistency and solids ratio to clean out the container (if you are transferring from a multi-purpose container to a bigger container). Add the water, mix and then add 6 ounces of pigment per gallon of solution. Mix for 2-3 minutes until the pigment is fully dispersed.

Epoxy Mixing Pro Tip

Using a power drill to mix epoxy ensures thorough mixing of the individual components into one homogeneous solution. Be careful not to overdo it, mixing too fast or near the surface can introduce excess air which can result in unwanted air bubbles in the solution.

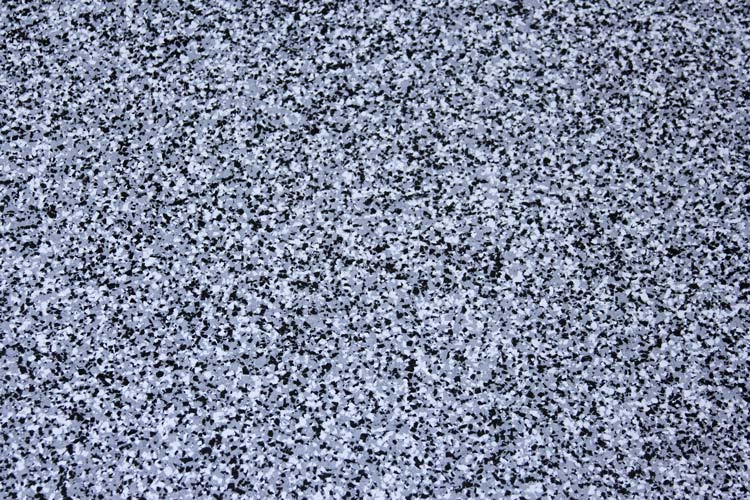

Begin this coat by cutting in walls/edges and cross joints. After you are finished cutting in pour the leftover material on the floor and evenly roll out the coating, make sure to cross and back roll to remove roller marks. Now, it’s time to broadcast (throw) the decorative flooring chips and flakes until rejection. Let the chip coat dry overnight.

24 Hours Later: Scrape Chips & Top Coat

Approximately 24 hours later, the chip coat should be dry and ready for scraping. Now you can crape the chips to break off any that are not smooth and flat against the floor. Make sure to scrape in multiple directions, we recommend 4 directions, to ensure that the surface is flat and smooth. Some applicators even lightly sand the chips to get an even smoother finish. When you're done scraping, recover the chips by sweeping them into piles and vacuuming them up with a shop vac.

Chip Scraping Pro Tip

You're lightly scraping the surface of the floor to remove any loose chips and break edges of chips sticking up. You are not supposed to be digging into the floor with the scraper. Scraping chips should feel smooth with little resistance, like you're gliding over the floor.

Now it’s time to prepare for the polyaspartic top coat. First, mix buckets A and B separately with a new paint stick each. With a new multi-purpose container, pour in 1 part A and 1 part B. Add 10 ounces of urethane grade solvent per gallon of polyaspartic. Mix with a clean paint stick for about 2 minutes. Cut-in to verticals, edges, and joints with the polyaspartic top coat. When done, pour the top coat in the middle of concrete squares and evenly roll out the polyaspartic coating. Cross roll to eliminate any lines and to ensure the coat is even.

Waterborne Epoxy Garage Floor Coating Photos

Slide-Lok Is The Most Trusted Name In Garage Makeovers Since 1977

Solid Products, Great Prices, and Timely Technical Support since 1977! Slide-Lok Garage Interiors is the oldest, longest continuing garage makeover brand in North America. We were the first one stop shop garage makeover for storage systems and flooring. We were also one of the first outfits to offer polyaspartic floor coatings to the residential garage flooring market. Our leading polyaspartic coatings have been in use on garage floors for nearly two decades, our competitors can't make that claim. We also manufacture and sell epoxy coatings that are great for indoor floors.

There are Authorized Slide-Lok Garage Flooring and Storage dealers all over the US and Canada that can transform your boring and dull garage into your dream garage. Every garage tells a different story, let us help tell yours.

So what are you waiting for, get your FREE ESTIMATE today: Contact Slide-Lok Garage Interiors.

Become a Slide-Lok Floor Coating & Cabinet Dealer

Expand your contracting business, there are more opportunities when you carry Slide-Lok Garage Interior products. Slide-Lok is your one stop shop for garage flooring and storage solutions since 1977. Inquire today and discover the benefits of Slide-Lok Garage Interiors.

About The Author

Quindrea Yazzie is a Phoenix-based journalist who specializes in digital content and client relations. Prior to Slide-lok, she has written for The State Press as an arts and culture reporter, AZ PBS as a digital producer and breaking news reporter and Indian Country Today as a reporter and producer. She earned a bachelor’s degree in Journalism and Mass Communication from the Walter Cronkite School of Journalism and Mass Communication at Arizona State University. When she is not writing, she enjoys running, trying new coffee blends, hiking and finding new ways to be sustainable.

Keywords: garage, floor, coatings, install, training, demo, flooring, epoxy, polyaspartic, waterborne, water, based, solvent, Buckeye, AZ, arizona, manufacturer

© Copyright, 2020, Slide-Lok (DBA), Mirabel Coatings Inc.

Back to Posts on The Home Improvement Blog

Contact Local Dealer

Find a Slide-Lok Garage Floor & Cabinet dealer in your area.

Call: 1-800-835-1759

E-mail: Click to e-mail.

Featured Blog Posts

- Concrete Coating System Adhesion Study

- We Want To Thank Our Suppliers!

- Closed July 2-5 for Independence Day

- Best Garage Floor Coatings in Phoenix, AZ

- New Flooring Chips and Flakes Brochure - Featuring 41 Colors!

- How To Choose The Right Color To Paint Your Garage

- 41 Stock Blends of Color Chips and Flakes for Floor Coatings

- 6 New Color Chips & Flakes for Floor Coatings

- Residential and Commercial Floor Coatings in Phoenix, Arizona

- 13 New Color Chips & Flakes for Floor Coatings

- 4 Home Improvement and Organizational Tips To Elevate Your Home

- Floor Coating Video

- Failed DIY Garage Floor Coating vs. Pro

- How To Get Smoother Top Coats, Chip and Flake Floor Coating Sealer

- Closed Labor Day Weekend Sept. 4-7

- Garage Floor Coating Transformation in Laramie, Wyoming

- Flooring Chips and Flakes Now Available By The Bucket

- Closed July 3-6 For Independence Day

- Fighting Allergies During COVID-19

- Become An Authorized Slide-Lok Floor Coating and Storage Installer

- Inventory Levels and Lead Times - Impacted Supply Chains

- Flooring Chips and Flakes Brochures

- Waterborne Epoxy Garage Floor Coating Training Video

- SBA Paycheck Protection Program - CARES ACT

- Spring Cleaning During Coronavirus Pandemic

- Staying Healthy: How To Minimize Your Risks Of Catching The Coronavirus (COVID-19)

- We Are Open, Taking & Shipping Orders

- When To Paint Your House - 5 Useful Tips For Interior Painting

- 10 Ideas For Your Garage Makeover

- Surviving WOC 2020: Coronavirus (COVID-19)

- The Best Time Of Year To Paint The Exterior Of Your Home

- Two Tone Chip Epoxy Floor in Mesa, Arizona

- Fitness Center Gets Metallic Epoxy Floor Coating

- Western Coating Societies Symposium and Show 2019

- Polyurea Is Better Than Polyaspartic?

- How To Improve Your Home's Curb Appeal

- 2 Tone Garage Floor Coating in Omaha, Nebraska

- Colorado Springs Garage Floor Restoration

- Polyaspartic Coating Survives as Boat Deck Coating

- Best Wasp & Hornet Pesticide Spray From Home Depot 2019

- Polyaspartic Flooring Withstands Flooding in Austin, Texas

- Garage Makeovers Shine in Florida

- Best Garage Remodels in Phoeniz, AZ

- Best Garage Makeovers of South Carolina

- Best Floor Coatings for Auto Mechanic Shops

- Garage Floor Coating Install in Anderson, IN

- DIY Epoxy Coating Repair in Casper, WY

- Polyaspartic Garage Floor Install in Pittsburgh, PA

- Garage Flooring & Painting in Omaha, Nebraska

- Concrete Coating Install in Eagan, Minnesota

- Garage Cabinet Installation in Wyoming, Michigan

- Garage Floor Coatings Albany, IN

Contact Local Dealer

Find a Slide-Lok Garage Floor & Cabinet dealer in your area.

Call: 1-800-835-1759

E-mail: Click to e-mail.

Featured Blog Posts

- Concrete Coating System Adhesion Study

- We Want To Thank Our Suppliers!

- Closed July 2-5 for Independence Day

- Best Garage Floor Coatings in Phoenix, AZ

- New Flooring Chips and Flakes Brochure - Featuring 41 Colors!

- How To Choose The Right Color To Paint Your Garage

- 41 Stock Blends of Color Chips and Flakes for Floor Coatings

- 6 New Color Chips & Flakes for Floor Coatings

- Residential and Commercial Floor Coatings in Phoenix, Arizona

- 13 New Color Chips & Flakes for Floor Coatings

- 4 Home Improvement and Organizational Tips To Elevate Your Home

- Floor Coating Video

- Failed DIY Garage Floor Coating vs. Pro

- How To Get Smoother Top Coats, Chip and Flake Floor Coating Sealer

- Closed Labor Day Weekend Sept. 4-7

- Garage Floor Coating Transformation in Laramie, Wyoming

- Flooring Chips and Flakes Now Available By The Bucket

- Closed July 3-6 For Independence Day

- Fighting Allergies During COVID-19

- Become An Authorized Slide-Lok Floor Coating and Storage Installer

- Inventory Levels and Lead Times - Impacted Supply Chains

- Flooring Chips and Flakes Brochures

- Waterborne Epoxy Garage Floor Coating Training Video

- SBA Paycheck Protection Program - CARES ACT

- Spring Cleaning During Coronavirus Pandemic

- Staying Healthy: How To Minimize Your Risks Of Catching The Coronavirus (COVID-19)

- We Are Open, Taking & Shipping Orders

- When To Paint Your House - 5 Useful Tips For Interior Painting

- 10 Ideas For Your Garage Makeover

- Surviving WOC 2020: Coronavirus (COVID-19)

- The Best Time Of Year To Paint The Exterior Of Your Home

- Two Tone Chip Epoxy Floor in Mesa, Arizona

- Fitness Center Gets Metallic Epoxy Floor Coating

- Western Coating Societies Symposium and Show 2019

- Polyurea Is Better Than Polyaspartic?

- How To Improve Your Home's Curb Appeal

- 2 Tone Garage Floor Coating in Omaha, Nebraska

- Colorado Springs Garage Floor Restoration

- Polyaspartic Coating Survives as Boat Deck Coating

- Best Wasp & Hornet Pesticide Spray From Home Depot 2019

- Polyaspartic Flooring Withstands Flooding in Austin, Texas

- Garage Makeovers Shine in Florida

- Best Garage Remodels in Phoeniz, AZ

- Best Garage Makeovers of South Carolina

- Best Floor Coatings for Auto Mechanic Shops

- Garage Floor Coating Install in Anderson, IN

- DIY Epoxy Coating Repair in Casper, WY

- Polyaspartic Garage Floor Install in Pittsburgh, PA

- Garage Flooring & Painting in Omaha, Nebraska

- Concrete Coating Install in Eagan, Minnesota

- Garage Cabinet Installation in Wyoming, Michigan

- Garage Floor Coatings Albany, IN