The Garage Makeover Blog by Slide-Lok

Polyurea Coatings Are "Better" Than Polyaspartics?

10/30/2019

Confusion Surrounding Polyurea and Polyaspartic Coatings

We are hearing throughout the country that some flooring contractors are selling and claiming that "Polyurea Is Better Than Polyaspartic". That's just not true. If you are hearing this, you may want to run. Either the person does not understand chemistry, or worse, is just trying to mislead.

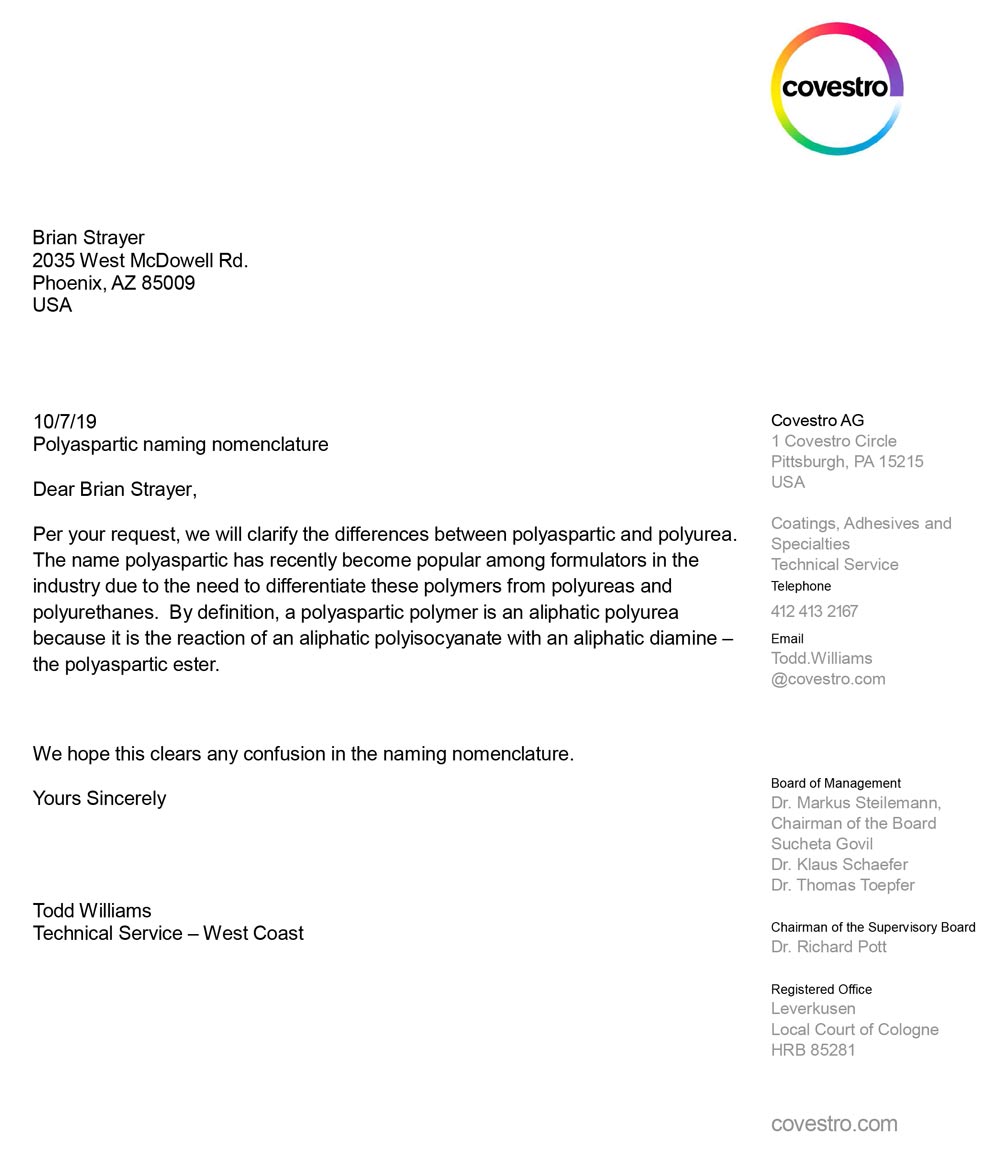

We have always known that Polyaspartics are Polyureas. But don’t take our word for it. We went straight to the people who invented and received the first patents for polyaspartic — Covestro, a world-leading supplier of high-tech polymer materials. Covestro, formerly Bayer MaterialScience, developed and patented the polyaspartic aliphatic polyurea chemistry technology. As you will discover reading this article, all polyaspartics are polyureas.

In the 1990's Bayer MaterialScience introduced a revolutionary new polymer they called polyaspartic, which is the reaction component of an aliphatic polyisocyanate and a aliphatic polyaspartic ester. Polyaspartics are aliphatic polyureas, and not all polyureas are aliphatic. Polyaspartic, aliphatic polyurea, formulations can be altered to adjust gel times (time it takes for a liquid to solidify) varying as much as 1 to 60+ minutes. This breakthrough meant that aliphatic polyureas, polyaspartics, were now versatile and could be used in nearly any application from flooring to corrosion protection without specialized application equipment. Conventional polyurea polymers are the reaction of aromatic polyisocyanates and aromatic amines that gel (turn from liquid to solid) in just a few seconds, meaning they require expensive and specialized application plural component spraying equipment (we'll touch more on this subject in next week's blog post).

The letter from Covestro, formerly Bayer MaterialScience, reads:

"Per your request, we will clarify the differences between polyaspartic and polyurea .... By definition, a polyaspartic polymer is an aliphatic polyurea because it is the reaction of an aliphatic polyisocyanate with an aliphatic diamine - the polyaspartic ester."

Todd Williams, Technical Service, Covestro AG

Polyaspartics Are Aliphatic Polyureas

The key takeaway here is that polyaspartic polymers are a type of polyurea, an aliphatic polyurea to be exact. However, not all polyurea polymers are true polyaspartics. This is because a polyaspartic is only created when you use an aliphatic polyisocyanate reacted with an aliphatic diamine - the polyaspartic ester. Conventional polyurea polymers on the other hand can be created using aromatic polyisocyanates and amines.

To understand the difference between aromatic and aliphatic compounds you will need to study up on your organic chemistry. Where aromatic compounds are unsaturated, aliphatic compounds can be both saturated and unsaturated. What matters in organic chemistry that applies to man-made coatings is that we use both aromatic and aliphatic compounds. Aliphatic paints and coatings like polyaspartics are light stable, better at resisting yellowing from UV exposure (sunlight) because they don't contain benzene rings. Aromatic compounds like conventional polyureas are susceptible to UV degradation because of the unsaturated benzene, more susceptible to photo degradation or attack from free radicals formed from the UV exposure.

Researchers have known about the inherent flaws of aromatic chemistry in the presence of UV light (sunlight) for quite some time. In fact, there's quite a bit of research on this topic, an example study is quoted below studying organic UV absorbers effect in hindering photodegradation of aromatic polymers. Currently there is no 100% aliphatic epoxy floor coating. Thus, all epoxy floor coatings and conventional polyureas contain aromatic compounds and are subject to UV photodegradation, yellowing, and impaired mechanical properties. Many coatings manufacturers claim UV stability in their epoxies, but all they have done is bought time as the study below shows delayed UV degradation when using organic UV absorbers in epoxy formulations. Aromatic coatings, which include epoxies and conventional polyureas are therefore not recommended for applications exposed to sunlight.

UV Photodegradation - 30% Reduction In Tensile Strength of Aromatic Epoxies

The Effects of UV Light on the Chemical and Mechanical Properties of a Transparent Epoxy-Diamine System in the Presence of an Organic UV Absorber

"UV light of sunlight forms free radicals on the surface of polymer-based materials ... These radicals are extremely active in attacking the polymeric structures ... these chemical bonds are prone to break and photodegradation occurs ... After an 800 h UV radiation, mechanical test results revealed that the lack of the UV absorber can lead to a ~30% reduction in tensile strength. However, in the presence of (UV Absorber), the tensile strength was reduced only by ~11%."

Saeid Nikafshar, Omid Zabihi, Mojtaba Ahmadi, Abdolreza Mirmohseni, Mojtaba Taseidifar, and Minoo Naebe. Various Departments of Chemistry, Physics and Engineering (click here for source).

CONCLUSION: Polyureas Are Not Better Than Polyaspartics

In summary, if you're being told "Polyurea coatings are better than polyaspartic coatings" you should probably RUN. This is FALSE, as polyaspartics are a type of polyurea. Anyone saying otherwise is praying on you not knowing any better, they are trying to cleverly confuse people. The polyaspartic naming convention was used to differentiate it from other polyureas and polyurethanes that are inferior in performance. Don't settle for a polyurea floor coating as it is most likely aromatic and susceptible to UV degradation (yellowing), and prone to adhesion or wetting issues since those materials gel in seconds versus 30-60 minutes for polyaspartics. Polyaspartic, aliphatic polyurea, coatings are better for flooring applications.

Since 1977

Slide-Lok Garage Interiors has been in business since 1977. We have honored our warranties for the past 42 years. While we have exceptionally outstanding products, occasionally a product fails due to unforeseen circumstances - that's just life. This is what sets us apart from our competitors, we have a long standing history of exceptional products and customer service. We'll let that speak for itself.

Letter From Covestro on Polyaspartic Naming Nomenclature

Letter from Covestro AG on 10/7/2019 titled "Polyaspartic naming nomenclature".

Articles Related to Polyaspartic Coatings

Covestro Letter On Polyaspartic Naming Nomenclature

Posted: 10/7/2019

Covestro letter to clarify polyaspartic naming convention. Polyaspartic is an aliphatic polyurea, a sub type of polyurea polymers. Conventional polyureas are aromatic, they are not the same thing.

comments

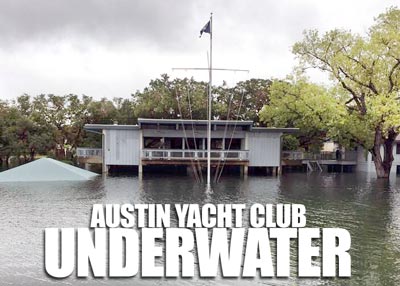

Polyaspartic Floor Coating Withstands Flooding in Austin, TX

Posted: 4/25/2019

In October of 2018, the Highland Lakes of Central Texas received significant rainfall resulting in massive flooding. The Austin Yacht Club was underwater for approximately 2 weeks. During cleanup and renovations the GM of the property discovered that our polyaspartic floor coating held up, and after a quick wash the floors looked brand new ...

comments

Best Floor Coatings for Auto Mechanic Shops - Commercial Flooring

Posted: 1/31/2019

Commercial flooring jobs keep our guys in Delaware pretty busy! We receive many phone calls about the best coating for auto mechanic shops. Learn what coatings we recommend and see our latest commercial floor install ...

comments

What Is The Best Garage Floor Coating?

Posted: 7/10/2018

Tired of searching the internet for the best garage floor coating? Trying to determine the most inexpensive, bargain, low cost, cheap or wholesale garage floor coatings? Here's our take on all the different coatings you can choose for your garage floor and why you should choose ...

comments

Why You Shouldn't Broadcast Chips Into The 1st Coat

Posted: 8/15/2017

We have heard that some floor coating contractors are now offering a 2 coat system, where they broadcast, or throw, the decorative chip into the base, or 1st coat, and then do a 2nd coat as a top coat. Some applicators ...

comments

Concrete Surface Preparation Methods For Resinous, Seamless Floor Coatings

Posted: 8/14/2017

We are often asked what is the best, most preferred method for preparing the surface of a concrete garage floor, concrete warehouse floor, aircraft hangar, restaurant, office or show room floor for a resinous coating. We tell applicators ...

comments

Become a Slide-Lok Floor Coating & Cabinet Dealer

Open your contracting business to more opportunities with Slide-Lok. Slide-Lok is your one stop shop for garage flooring and storage solutions since 1977. Inquire today and discover the benefits of Slide-Lok Garage Interiors.

About The Author

Samuel Strayer is a trained chemist with a Bachelor of Science in Biochemistry from Arizona State University with an emphasis on material and polymer science. Samuel has been involved in developing and testing coating systems for over 10 years.

Keywords: polyurea, polyaspartic, aliphatic, epoxy, polyurethane, coatings, covestro, bayer, material, science, flooring, floors

© Copyright, 2019, Slide-Lok (DBA), Mirabel Coatings Inc.

Back to Posts on The Garage Makeover Blog

Contact Local Dealer

Find a Slide-Lok Garage Floor & Cabinet dealer in your area.

Call: 1-800-835-1759

E-mail: Click to e-mail.

Featured Blog Posts

- Concrete Coating System Adhesion Study

- We Want To Thank Our Suppliers!

- Closed July 2-5 for Independence Day

- Best Garage Floor Coatings in Phoenix, AZ

- New Flooring Chips and Flakes Brochure - Featuring 41 Colors!

- How To Choose The Right Color To Paint Your Garage

- 41 Stock Blends of Color Chips and Flakes for Floor Coatings

- 6 New Color Chips & Flakes for Floor Coatings

- Residential and Commercial Floor Coatings in Phoenix, Arizona

- 13 New Color Chips & Flakes for Floor Coatings

- 4 Home Improvement and Organizational Tips To Elevate Your Home

- Floor Coating Video

- Failed DIY Garage Floor Coating vs. Pro

- How To Get Smoother Top Coats, Chip and Flake Floor Coating Sealer

- Closed Labor Day Weekend Sept. 4-7

- Garage Floor Coating Transformation in Laramie, Wyoming

- Flooring Chips and Flakes Now Available By The Bucket

- Closed July 3-6 For Independence Day

- Fighting Allergies During COVID-19

- Become An Authorized Slide-Lok Floor Coating and Storage Installer

- Inventory Levels and Lead Times - Impacted Supply Chains

- Flooring Chips and Flakes Brochures

- Waterborne Epoxy Garage Floor Coating Training Video

- SBA Paycheck Protection Program - CARES ACT

- Spring Cleaning During Coronavirus Pandemic

- Staying Healthy: How To Minimize Your Risks Of Catching The Coronavirus (COVID-19)

- We Are Open, Taking & Shipping Orders

- When To Paint Your House - 5 Useful Tips For Interior Painting

- 10 Ideas For Your Garage Makeover

- Surviving WOC 2020: Coronavirus (COVID-19)

- The Best Time Of Year To Paint The Exterior Of Your Home

- Two Tone Chip Epoxy Floor in Mesa, Arizona

- Fitness Center Gets Metallic Epoxy Floor Coating

- Western Coating Societies Symposium and Show 2019

- Polyurea Is Better Than Polyaspartic?

- How To Improve Your Home's Curb Appeal

- 2 Tone Garage Floor Coating in Omaha, Nebraska

- Colorado Springs Garage Floor Restoration

- Polyaspartic Coating Survives as Boat Deck Coating

- Best Wasp & Hornet Pesticide Spray From Home Depot 2019

- Polyaspartic Flooring Withstands Flooding in Austin, Texas

- Garage Makeovers Shine in Florida

- Best Garage Remodels in Phoeniz, AZ

- Best Garage Makeovers of South Carolina

- Best Floor Coatings for Auto Mechanic Shops

- Garage Floor Coating Install in Anderson, IN

- DIY Epoxy Coating Repair in Casper, WY

- Polyaspartic Garage Floor Install in Pittsburgh, PA

- Garage Flooring & Painting in Omaha, Nebraska

- Concrete Coating Install in Eagan, Minnesota

- Garage Cabinet Installation in Wyoming, Michigan

- Garage Floor Coatings Albany, IN

Contact Local Dealer

Find a Slide-Lok Garage Floor & Cabinet dealer in your area.

Call: 1-800-835-1759

E-mail: Click to e-mail.

Featured Blog Posts

- Concrete Coating System Adhesion Study

- We Want To Thank Our Suppliers!

- Closed July 2-5 for Independence Day

- Best Garage Floor Coatings in Phoenix, AZ

- New Flooring Chips and Flakes Brochure - Featuring 41 Colors!

- How To Choose The Right Color To Paint Your Garage

- 41 Stock Blends of Color Chips and Flakes for Floor Coatings

- 6 New Color Chips & Flakes for Floor Coatings

- Residential and Commercial Floor Coatings in Phoenix, Arizona

- 13 New Color Chips & Flakes for Floor Coatings

- 4 Home Improvement and Organizational Tips To Elevate Your Home

- Floor Coating Video

- Failed DIY Garage Floor Coating vs. Pro

- How To Get Smoother Top Coats, Chip and Flake Floor Coating Sealer

- Closed Labor Day Weekend Sept. 4-7

- Garage Floor Coating Transformation in Laramie, Wyoming

- Flooring Chips and Flakes Now Available By The Bucket

- Closed July 3-6 For Independence Day

- Fighting Allergies During COVID-19

- Become An Authorized Slide-Lok Floor Coating and Storage Installer

- Inventory Levels and Lead Times - Impacted Supply Chains

- Flooring Chips and Flakes Brochures

- Waterborne Epoxy Garage Floor Coating Training Video

- SBA Paycheck Protection Program - CARES ACT

- Spring Cleaning During Coronavirus Pandemic

- Staying Healthy: How To Minimize Your Risks Of Catching The Coronavirus (COVID-19)

- We Are Open, Taking & Shipping Orders

- When To Paint Your House - 5 Useful Tips For Interior Painting

- 10 Ideas For Your Garage Makeover

- Surviving WOC 2020: Coronavirus (COVID-19)

- The Best Time Of Year To Paint The Exterior Of Your Home

- Two Tone Chip Epoxy Floor in Mesa, Arizona

- Fitness Center Gets Metallic Epoxy Floor Coating

- Western Coating Societies Symposium and Show 2019

- Polyurea Is Better Than Polyaspartic?

- How To Improve Your Home's Curb Appeal

- 2 Tone Garage Floor Coating in Omaha, Nebraska

- Colorado Springs Garage Floor Restoration

- Polyaspartic Coating Survives as Boat Deck Coating

- Best Wasp & Hornet Pesticide Spray From Home Depot 2019

- Polyaspartic Flooring Withstands Flooding in Austin, Texas

- Garage Makeovers Shine in Florida

- Best Garage Remodels in Phoeniz, AZ

- Best Garage Makeovers of South Carolina

- Best Floor Coatings for Auto Mechanic Shops

- Garage Floor Coating Install in Anderson, IN

- DIY Epoxy Coating Repair in Casper, WY

- Polyaspartic Garage Floor Install in Pittsburgh, PA

- Garage Flooring & Painting in Omaha, Nebraska

- Concrete Coating Install in Eagan, Minnesota

- Garage Cabinet Installation in Wyoming, Michigan

- Garage Floor Coatings Albany, IN