Garage Floor Coating Installed in Anderson, Indiana

1/17/2019

In order to remove the old epoxy coating and get to a nice clean surface for coating you have to grind the floor. Grinding or Shot blasting a floor is among the best prep methods available.

In order to remove the old epoxy coating and get to a nice clean surface for coating you have to grind the floor. Grinding or Shot blasting a floor is among the best prep methods available.  This is before we took the diamond grinder to the concrete. Look at how nasty that looks! The rusted circular piece is an old solid metal stud in the floor. This had to be ground smooth.

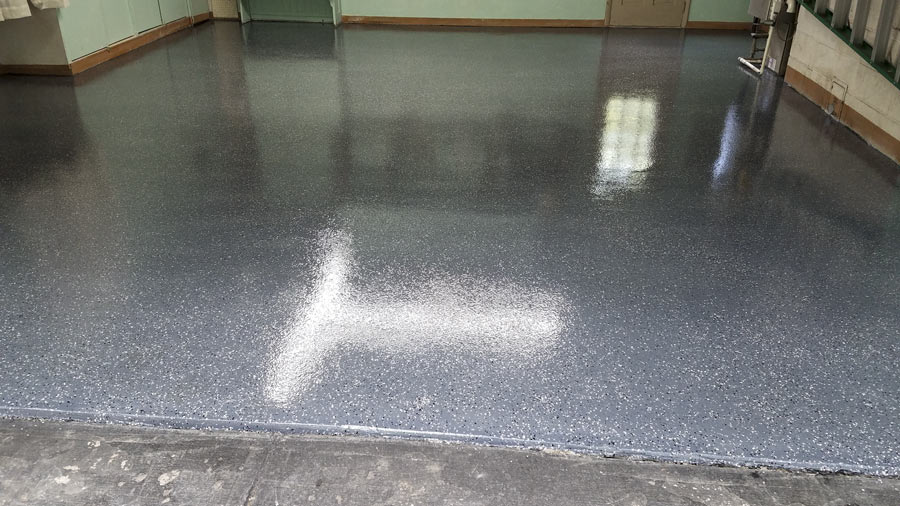

This is before we took the diamond grinder to the concrete. Look at how nasty that looks! The rusted circular piece is an old solid metal stud in the floor. This had to be ground smooth. Wow! Look how clean this garage floor looks now. This is a 3 coat polyaspartic garage floor with partial tech silver chip broadcast and anti-slip silica.

Wow! Look how clean this garage floor looks now. This is a 3 coat polyaspartic garage floor with partial tech silver chip broadcast and anti-slip silica.Old Garage Floor Gets New Life with Polyaspartic Coating

This garage is located in Anderson, a small city just northeast of Indianapolis, Indiana. A nice elderly lady had just purchased this home a few years ago. She was tired of pulling into the garage with an old nasty looking epoxy coating on it. She called Slide-Lok of Indianapolis to come take a look and provide a free estimate. She was so excited to get her garage floor coating installed she immediately scheduled the install.

This floor was in a very rough state prior to the flooring team's arrival. There were cracks all over, a failed and peeling epoxy coating, and two solid metal studs in the floor. The team set to work on grinding flat the metal studs. The metal studs had to be ground flat against the concrete to provide a smooth seamless look that the homeowner was looking for. The flooring crew then began to diamond grind the concrete to a profile similar to 60-80 grit sandpaper, which is needed to ensure flooring success and longevity. After the old epoxy was ground off and a fresh new porous concrete surface exposed the repair work was ready to begin. Repairs included filling 1 large crack and the 2 areas where the metal studs were located with a polyurethane crack filler. Once the crack repairs were made the floor was ready for a coating. The coating process involved 3 coats of our famous polyaspartic flooring system. The middle or second coat received a partial broadcast of tech silver chips. Finally, the top coat received a sprinkling of anti-slip silica to aid slip resistance by increasing the coefficient of friction of the floor.

Anti-slip additive is a fine granular silica additive that can be mixed into the top coat or broadcast over the top of the final coat. This silica protrudes from the floor helping to increase the coefficient of friction of the floor to aid in slip resistance. Anti-slip additive does not guarantee that the floor is 100% slip-resistant, it merely helps provide a little more traction. All local flooring contractors are responsible for making sure that their use of anti-slip additive in public places meets local building codes.

The homeowner was very happy with the finished result. As you can see above, it's a very beautiful garage floor. These kinds of garage flooring transformations are not uncommon. Your garage floor is just one day away from looking like this good.

Get your FREE ESTIMATE today: Contact Slide-Lok Garage Interiors.

Local Slide-Lok of Indianapolis Dealer Info

Call: (317) 828-0170

email: click here to e-mail Indianapolis dealer

About The Author

Samuel Strayer is a trained chemist with a Bachelor of Science in Biochemistry from Arizona State University with an emphasis on material and polymer science. Samuel has been involved in developing and testing coating systems for over 10 years.

Keywords: Garage, Floor, Flooring, Coatings, Coating, Epoxy, Polyaspartic, Anderson, Indiana

© Copyright, 2019, Slide-Lok (DBA), Mirabel Coatings Inc.

Back to Posts on The Garage Blog

Featured Blog Posts

- Concrete Coating System Adhesion Study

- We Want To Thank Our Suppliers!

- Closed July 2-5 for Independence Day

- Best Garage Floor Coatings in Phoenix, AZ

- New Flooring Chips and Flakes Brochure - Featuring 41 Colors!

- How To Choose The Right Color To Paint Your Garage

- 41 Stock Blends of Color Chips and Flakes for Floor Coatings

- 6 New Color Chips & Flakes for Floor Coatings

- Residential and Commercial Floor Coatings in Phoenix, Arizona

- 13 New Color Chips & Flakes for Floor Coatings

- 4 Home Improvement and Organizational Tips To Elevate Your Home

- Floor Coating Video

- Failed DIY Garage Floor Coating vs. Pro

- How To Get Smoother Top Coats, Chip and Flake Floor Coating Sealer

- Closed Labor Day Weekend Sept. 4-7

- Garage Floor Coating Transformation in Laramie, Wyoming

- Flooring Chips and Flakes Now Available By The Bucket

- Closed July 3-6 For Independence Day

- Fighting Allergies During COVID-19

- Become An Authorized Slide-Lok Floor Coating and Storage Installer

- Inventory Levels and Lead Times - Impacted Supply Chains

- Flooring Chips and Flakes Brochures

- Waterborne Epoxy Garage Floor Coating Training Video

- SBA Paycheck Protection Program - CARES ACT

- Spring Cleaning During Coronavirus Pandemic

- Staying Healthy: How To Minimize Your Risks Of Catching The Coronavirus (COVID-19)

- We Are Open, Taking & Shipping Orders

- When To Paint Your House - 5 Useful Tips For Interior Painting

- 10 Ideas For Your Garage Makeover

- Surviving WOC 2020: Coronavirus (COVID-19)

- The Best Time Of Year To Paint The Exterior Of Your Home

- Two Tone Chip Epoxy Floor in Mesa, Arizona

- Fitness Center Gets Metallic Epoxy Floor Coating

- Western Coating Societies Symposium and Show 2019

- Polyurea Is Better Than Polyaspartic?

- How To Improve Your Home's Curb Appeal

- 2 Tone Garage Floor Coating in Omaha, Nebraska

- Colorado Springs Garage Floor Restoration

- Polyaspartic Coating Survives as Boat Deck Coating

- Best Wasp & Hornet Pesticide Spray From Home Depot 2019

- Polyaspartic Flooring Withstands Flooding in Austin, Texas

- Garage Makeovers Shine in Florida

- Best Garage Remodels in Phoeniz, AZ

- Best Garage Makeovers of South Carolina

- Best Floor Coatings for Auto Mechanic Shops

- Garage Floor Coating Install in Anderson, IN

- DIY Epoxy Coating Repair in Casper, WY

- Polyaspartic Garage Floor Install in Pittsburgh, PA

- Garage Flooring & Painting in Omaha, Nebraska

- Concrete Coating Install in Eagan, Minnesota

- Garage Cabinet Installation in Wyoming, Michigan

- Garage Floor Coatings Albany, IN

Contact Local Dealer

Find a Slide-Lok Garage Floor & Cabinet dealer in your area.

Call: 1-800-835-1759

E-mail: Click to e-mail.

Featured Blog Posts

- Concrete Coating System Adhesion Study

- We Want To Thank Our Suppliers!

- Closed July 2-5 for Independence Day

- Best Garage Floor Coatings in Phoenix, AZ

- New Flooring Chips and Flakes Brochure - Featuring 41 Colors!

- How To Choose The Right Color To Paint Your Garage

- 41 Stock Blends of Color Chips and Flakes for Floor Coatings

- 6 New Color Chips & Flakes for Floor Coatings

- Residential and Commercial Floor Coatings in Phoenix, Arizona

- 13 New Color Chips & Flakes for Floor Coatings

- 4 Home Improvement and Organizational Tips To Elevate Your Home

- Floor Coating Video

- Failed DIY Garage Floor Coating vs. Pro

- How To Get Smoother Top Coats, Chip and Flake Floor Coating Sealer

- Closed Labor Day Weekend Sept. 4-7

- Garage Floor Coating Transformation in Laramie, Wyoming

- Flooring Chips and Flakes Now Available By The Bucket

- Closed July 3-6 For Independence Day

- Fighting Allergies During COVID-19

- Become An Authorized Slide-Lok Floor Coating and Storage Installer

- Inventory Levels and Lead Times - Impacted Supply Chains

- Flooring Chips and Flakes Brochures

- Waterborne Epoxy Garage Floor Coating Training Video

- SBA Paycheck Protection Program - CARES ACT

- Spring Cleaning During Coronavirus Pandemic

- Staying Healthy: How To Minimize Your Risks Of Catching The Coronavirus (COVID-19)

- We Are Open, Taking & Shipping Orders

- When To Paint Your House - 5 Useful Tips For Interior Painting

- 10 Ideas For Your Garage Makeover

- Surviving WOC 2020: Coronavirus (COVID-19)

- The Best Time Of Year To Paint The Exterior Of Your Home

- Two Tone Chip Epoxy Floor in Mesa, Arizona

- Fitness Center Gets Metallic Epoxy Floor Coating

- Western Coating Societies Symposium and Show 2019

- Polyurea Is Better Than Polyaspartic?

- How To Improve Your Home's Curb Appeal

- 2 Tone Garage Floor Coating in Omaha, Nebraska

- Colorado Springs Garage Floor Restoration

- Polyaspartic Coating Survives as Boat Deck Coating

- Best Wasp & Hornet Pesticide Spray From Home Depot 2019

- Polyaspartic Flooring Withstands Flooding in Austin, Texas

- Garage Makeovers Shine in Florida

- Best Garage Remodels in Phoeniz, AZ

- Best Garage Makeovers of South Carolina

- Best Floor Coatings for Auto Mechanic Shops

- Garage Floor Coating Install in Anderson, IN

- DIY Epoxy Coating Repair in Casper, WY

- Polyaspartic Garage Floor Install in Pittsburgh, PA

- Garage Flooring & Painting in Omaha, Nebraska

- Concrete Coating Install in Eagan, Minnesota

- Garage Cabinet Installation in Wyoming, Michigan

- Garage Floor Coatings Albany, IN

Contact Local Dealer

Find a Slide-Lok Garage Floor & Cabinet dealer in your area.

Call: 1-800-835-1759

E-mail: Click to e-mail.