The Garage Makeover Blog by Slide-Lok

Western Coatings Societies Symposium and Show 2019

11/14/2019

Coatings Industry: New Technologies, News & Regulatory Changes from WCS 2019

As one of the R&D / formulation chemists I am tasked with staying up to date on the latest coatings trends, technologies, developments and ever evolving regulatory changes that impact our industry. As such I have been to many World of Concrete shows in Vegas, Radtech UV/EB Coatings Show in Chicago, and this was my first time attending WCS.

WCS Overview

"The WCS is a regional conference and trade show serving primarily, but not exclusively, Western USA and Canada. We aim to provide educational and networking opportunities for technical individuals involved in the development and manufacturing of coatings, their employers, and related venders in the Coatings Industry. Our show includes a three-day technical program, a two-day tabletop exhibition, and opportunities for socializing and networking."

Western Coating Societies' Website

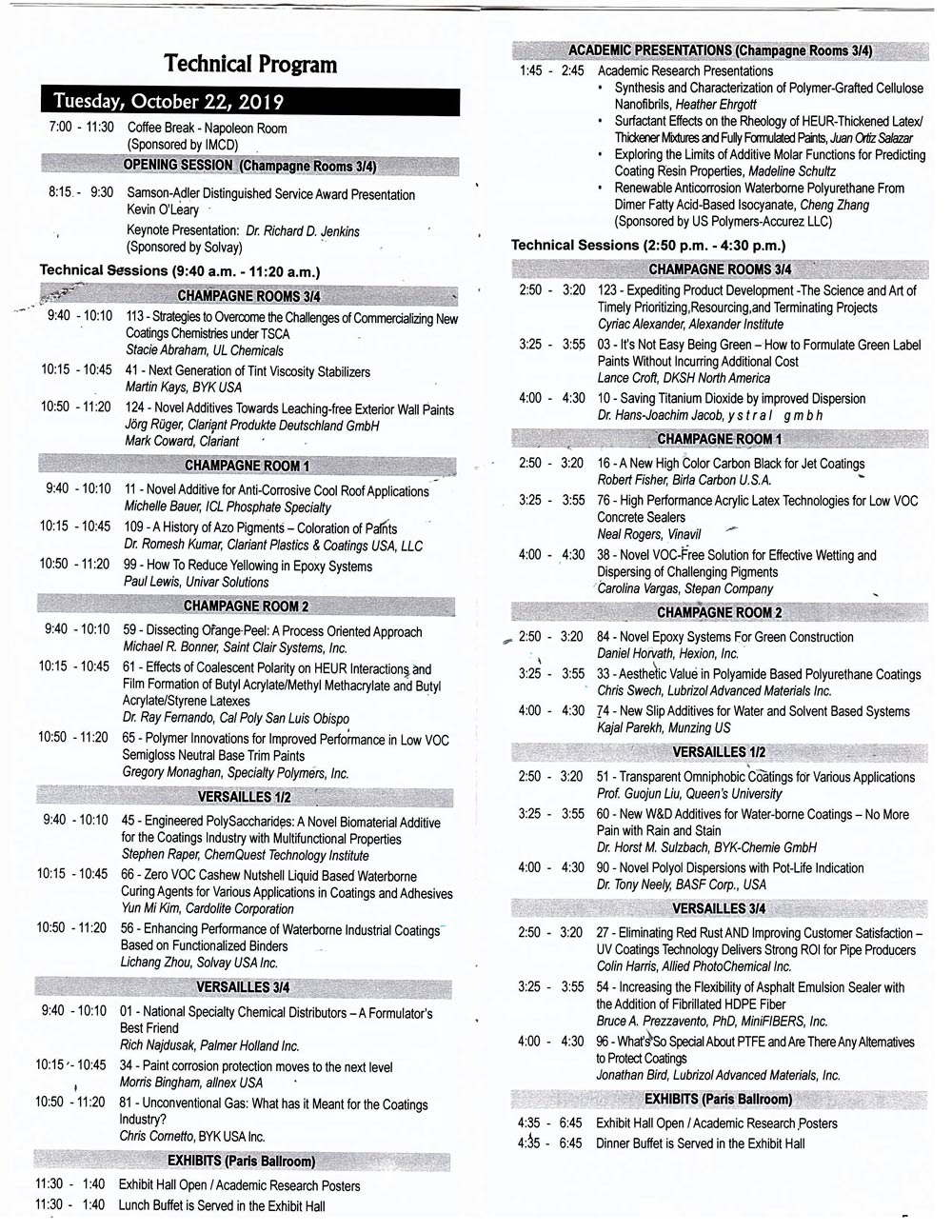

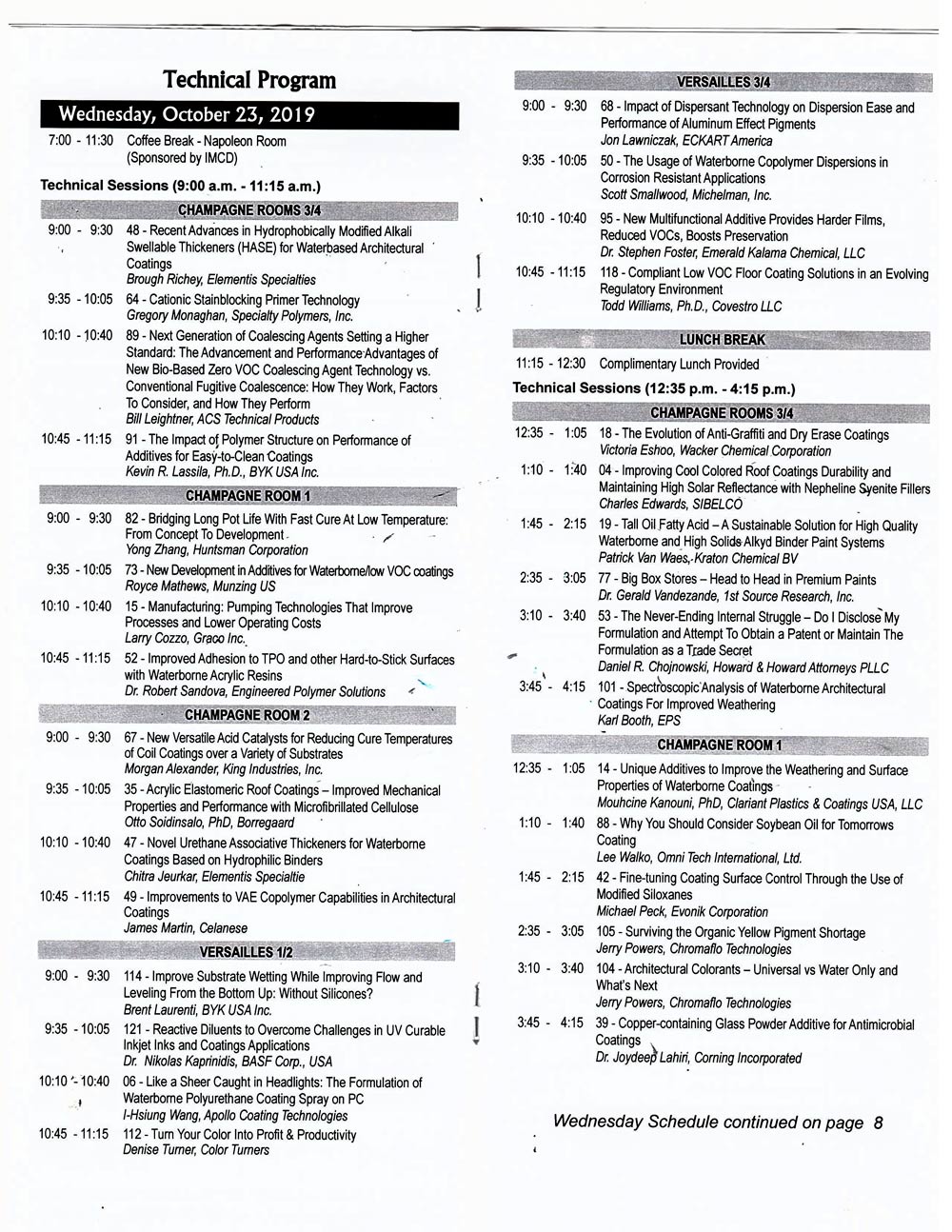

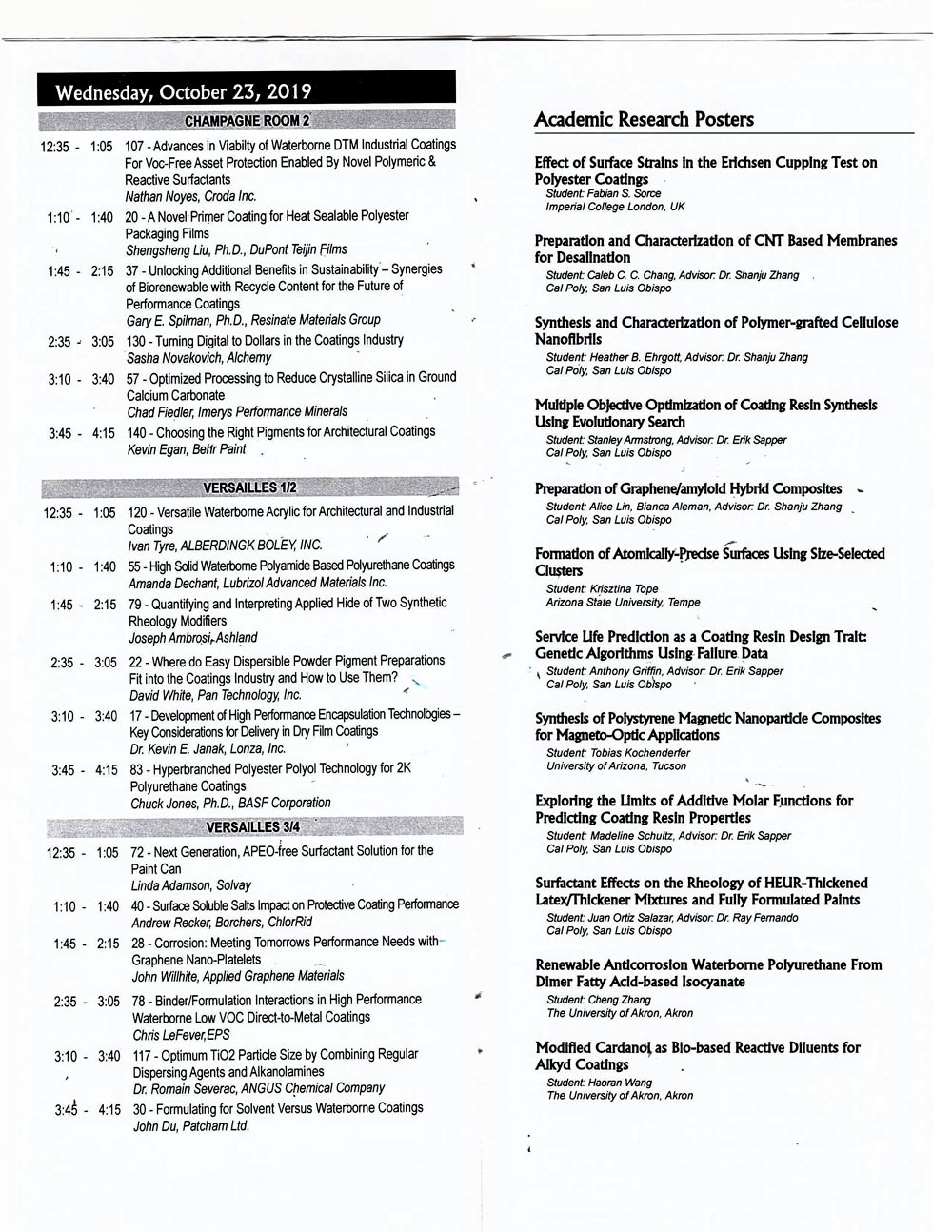

Reflecting On The Western Coatings Show

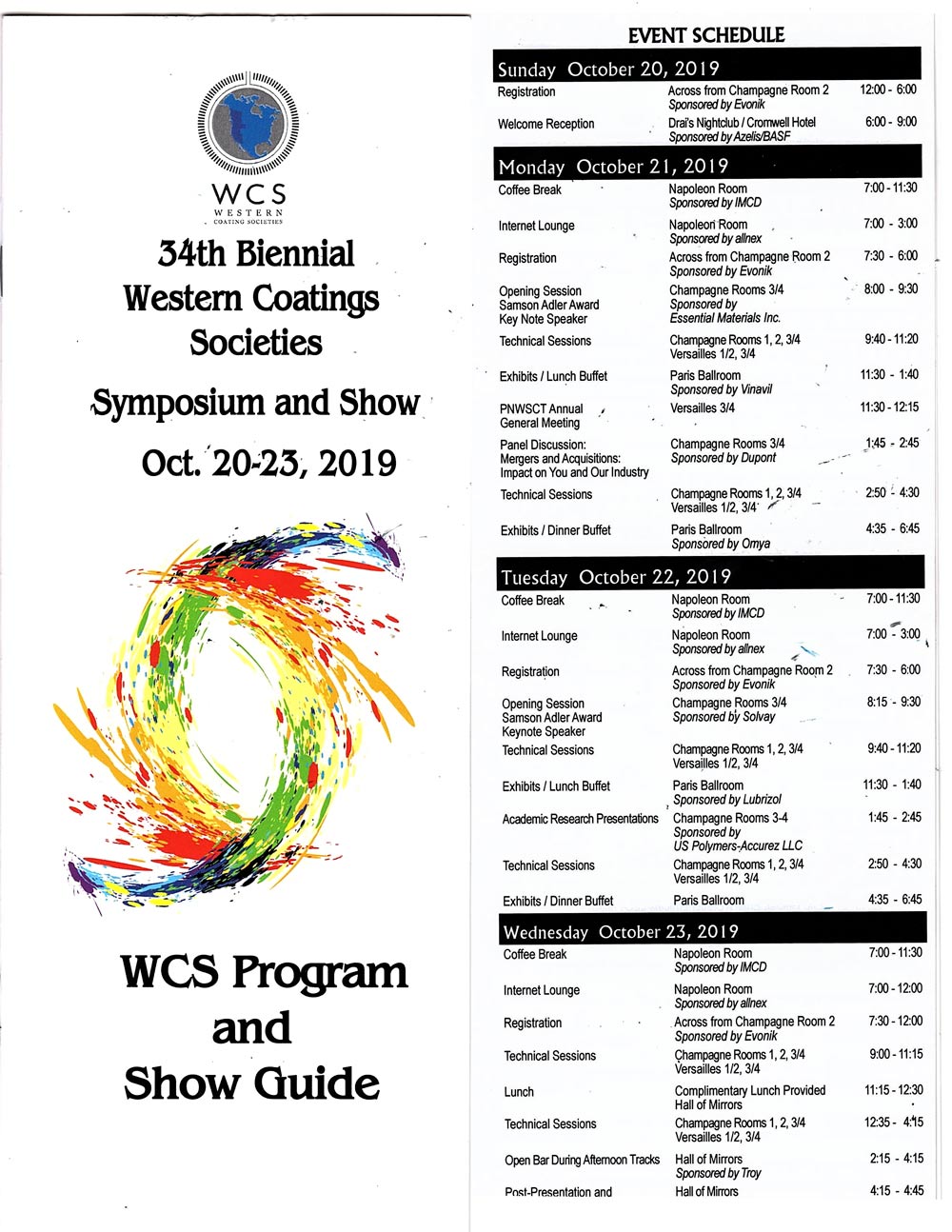

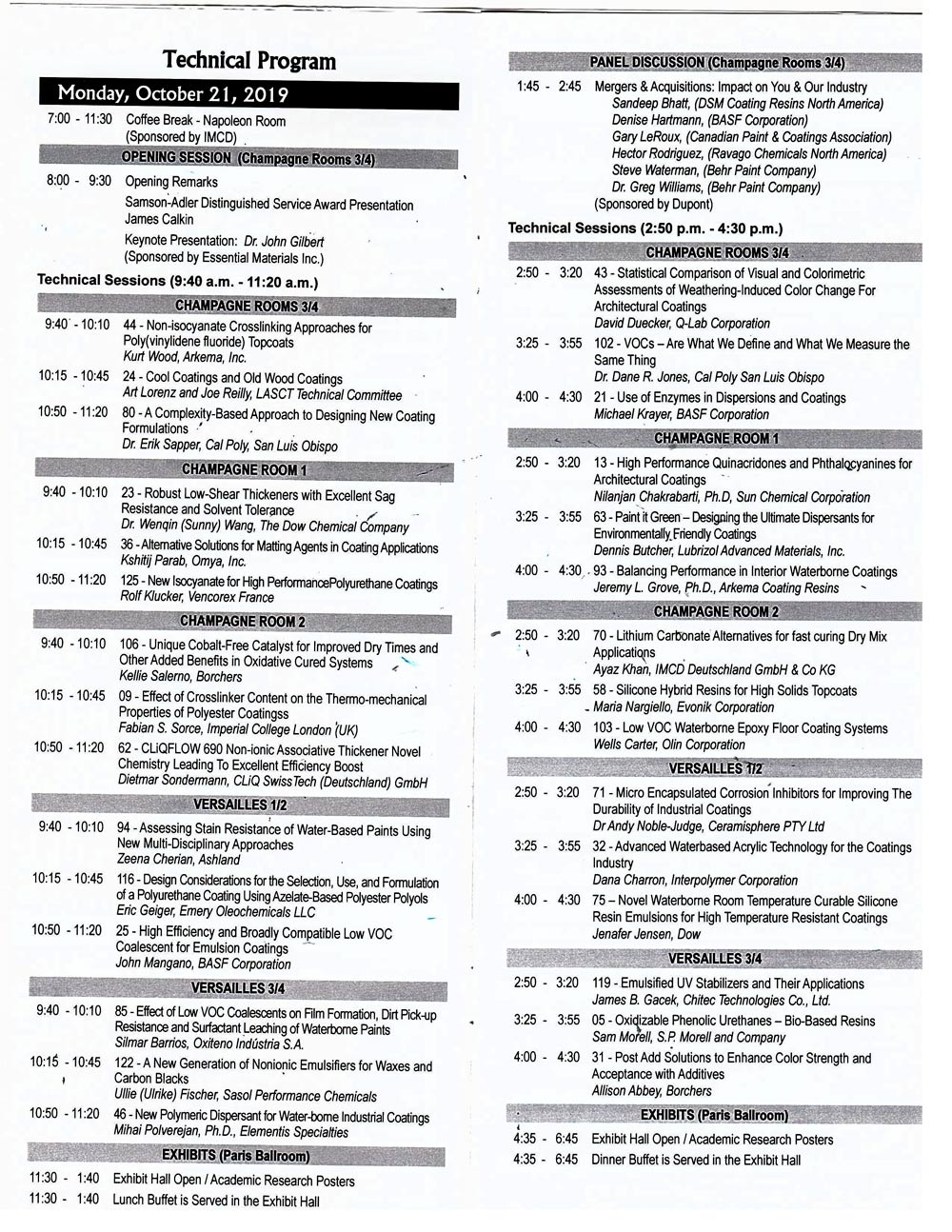

The WCS ended a few weeks ago (October 20-23) and I am finally back in my normal routine of working on coatings formulations and providing technical support. So what are my takeaways from the show? First off, this trade show is quite unlike others, in between every break period there was coffee and catered food - real good food too! The trade show hall was only open a few hours each day, their way of encouraging you to attend the technical presentations in the interim. I was able to attend all the panels I was interested in. To give you an idea of the topics covered at the coatings show here are the titles to 8 out of the 100+ scheduled presentations:

WCS Technical Presentations

"Silicone aliphatic polyester resins combine the high chemical and weathering resistance of silicone polymers with the flexibility and adhesion of polyesters. Once cross-linked, these polymers can be formulated to..."

Maria Nargiello, Head of Applied Research & Technology - Americas, Evonik Corporation

"Silicone Release Coatings continue to improve with easier application and performance characteristics. The environmental impact and consumer safety concerns have also been addressed in the latest offerings. Products have improved so much that they are now available in the DIY market. These changes open new markets for formulators. Improvements in Silicone Release Coatings in the anti-graffiti category include moving away from the oxime-based chemistry and total elimination of metal catalysts. The newer generation of products are amine-catalysed, moisture cure, 1K (single component), and RTV (Room-Temperature-Vulcanizing silicone) systems. Both generations lessen the environmental impact as neither requires harsh chemicals to remove graffiti..."

Victoria Eshoo, Chemist, Wacker Chemical Corporation

Low VOC Waterborne Epoxy Floor Coating Systems

"The popularity of waterborne (WB) coatings has increased primarily driven by the desire to reduce the presence of volatile organic compounds (VOCs) and their impact on human health and the environment..."

Wells Carter, Olin Corporation

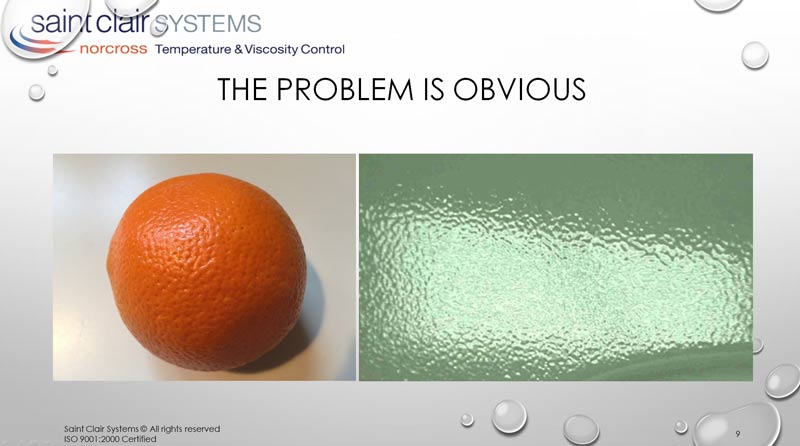

"... we present the results of an in-depth design-of-experiments conceived to identify the impact of, and interaction between, critical process parameters and the outcome of the clearcoat process – focusing specifically on orange peel..."

Michael R. Bonner, VP of Engineering & Technology, Saint Clair Systems, Inc.

Zero VOC Cashew Nutshell Liquid Based Waterborne Curing Agents For Various Applications In Coatings and Adhesives

"These solvent free WB curing agents have demonstrated very desirable performances including faster cure at low temperature, excellent anti-corrosion performances, outstanding adhesion to various substrates, and good compatibility with both standard bisphenol A/F type resin..."

Yun Mi Kim, Cardolite Corporation

"It is well established that conventional epoxy coatings and encapsulation products will yellow rapidly when exposed to sunlight..."

Paul Lewis, Technical Manager of Formulation Laboratory, Univar Solutions

New Slip Additives For Water And Solvent Based Systems

"... organo-modified polysiloxane technology were designed to provide excellent slip and improved scratch resistance in both water and solvent based systems. Even at low dosages, they demonstrate a strong reduction in the coefficient of friction (COF)..."

Kajal Parekh, Lab Manager, Munzing US

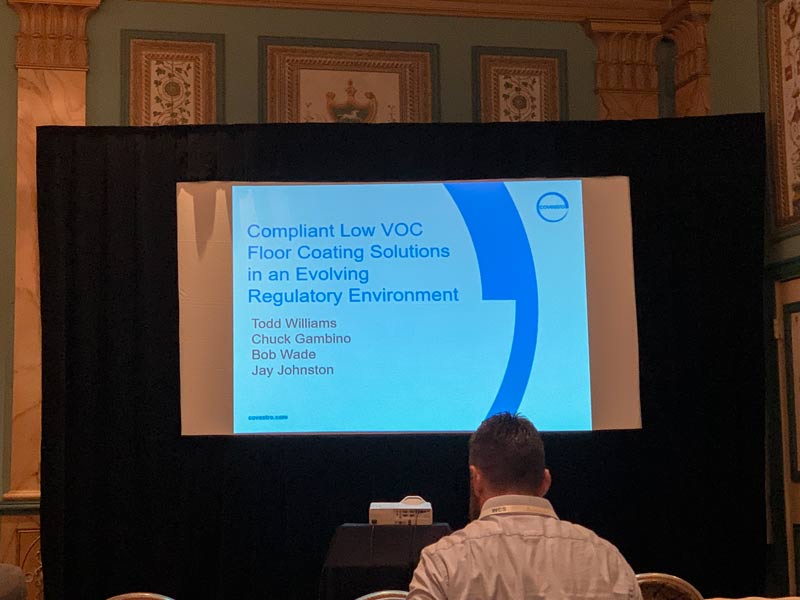

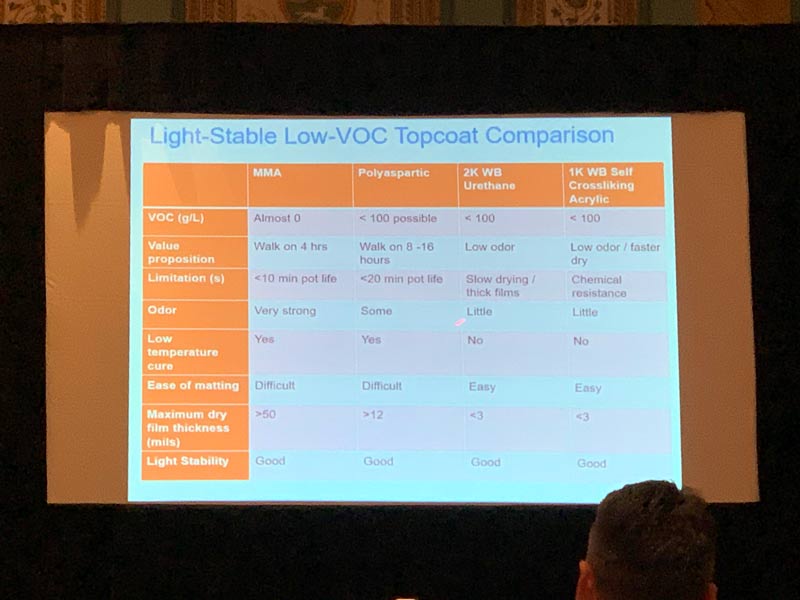

"In light of the ever changing VOC regulations in the United States ... Several technologies have been developed to address the market including waterborne and very high solids epoxy, polyaspartic, one / two component waterborne urethanes and often times these are used in conjunction with each other..."

Todd Williams, Ph.D., Product & Tech Service - Coatings, Adhesives & Specialties, Covestro LLC

That's just 8 out of 100+ presentations that took place over the course of 3 days at the show. There were so many presentation that 5 were running concurrently. It's impossible to sit through all of the presentations, you have to pick topics that are most important to you / your business and miss the less important ones. I really enjoyed some of the talks.

Evolving Regulatory Status of Exempt Solvents

Many of the challenges facing our industry are the evolving regulatory changes that seem to spawn from California. The talk of the show was California, rather the South Coast Air Quality Management District (SCAQMD), phasing out Parachlorobenzotrifluoride (PCBTF or Oxol) due to a carcinogenic/toxicology report that might require listing it on Prop. 65. I think that report is still under review because there is no certainty yet, but everyone should be planning on PCBTF / Oxol to have its exempt solvent status revoked. Once the SCAQMD issues its decision on Oxol various other regulatory bodies throughout the country follow suit, at which point its EPA exempt status will likely change.

The EPA regulates VOC emissions in many industries including paints and coatings. Oxol is a beneficial solvent used in solventborne 2K / two component coating formulations. Over the years Oxol and Acetone have been widely used together in order to achieve excellent pot life, film coalescence, and good solvent evaporation rates for 2k solventborne coatings. When Oxol gets delisted, this will affect many coatings manufacturers that rely on Oxol to slide under VOC regulations. Without Oxol, Acetone is almost useless because it is not as beneficial a solvent on its own.

This is a good reminder to coatings manufacturers to start evaluating alternative formulations using new low or zero VOC solvents if you haven't already. There were many presentations on alternative Low VOC formulations for epoxies, urethanes, and polyaspartics. We have been evaluating low odor and lower VOC formulations for quite some time, so it is good reassurance that we're working on the right projects. We plan to have low VOC, low odor formulations of our polyaspartic coatings available soon.

Multiple Solutions To Reformulating Coatings

There were several panels on low VOC formulations of various products such as epoxies, urethanes and polyaspartics; using hyperbranched polymer technology, exempt or bio-based solvents in order to create low viscosity and low VOC coatings. Part of the problem in removing solvents is losing their excellent qualities they impart on lowering viscosity of coating systems to suitable application levels. The problem with solvents is finding ones that offer useful evaporation rates, system compatibility/incompatibility, and navigating their ever evolving regulatory status. Traditional solvents that have been used in paints and coatings include toluene, xylene and many more, many are derived from the petrochemical industry, refined petroleum distillates. These solvents are considered volatile organic compounds (VOCs) because they generally have high vapor pressures at normal temperatures, which translates to low boiling points making these chemicals evaporate quickly into our atmosphere. VOC labeled solvents are different than other solvents which evaporate because they can react in the atmosphere to form ozone, part of the reason they're regulated. Believe it or not water can be used as a solvent, but it is not considered a VOC.

There are solutions to addressing low VOC and low viscosity formulations. As mentioned above the panelists talked about new coatings formulations using hyperbranched polymers and various exempted or low VOC solvents. One solution is using exempt solvents or solvents with low VOC levels, or low maximum incremental reactivity (MIR) levels. Another solution is using hyperbranched polymers, they allow for large molecules to be lower viscosity than conventional long chain saturated molecules with high viscosity. What's so unique about hyperbranched polymers is that they are highly branched, 3-dimensional macromolecules that can be tailored in functionality and reactive groups. Since hyperbranched molecules are spherical in shape their long chains doen't easily get tangled with other molecules so to speak, thus they're lower viscosity compared to similar length molecules that do entangle other molecules resulting in higher viscosities.

The Food Was Good Too

It may not surprise anyone to find out that the show's organizers included lunch, evening appetizers, desserts and beverages during the show. Which in no doubt is probably why the registration cost for this show was upwards of $400, there is no such thing as a free lunch after all. The "complimentary" food was nice, but really uneccessary since I only got to enjoy it once. I planned my trip to the WCS well in advance and I had arranged meetings with various suppliers over breakfast, lunch and dinner for all but one meal during the three days of the show.

Wrapping Up The WCS

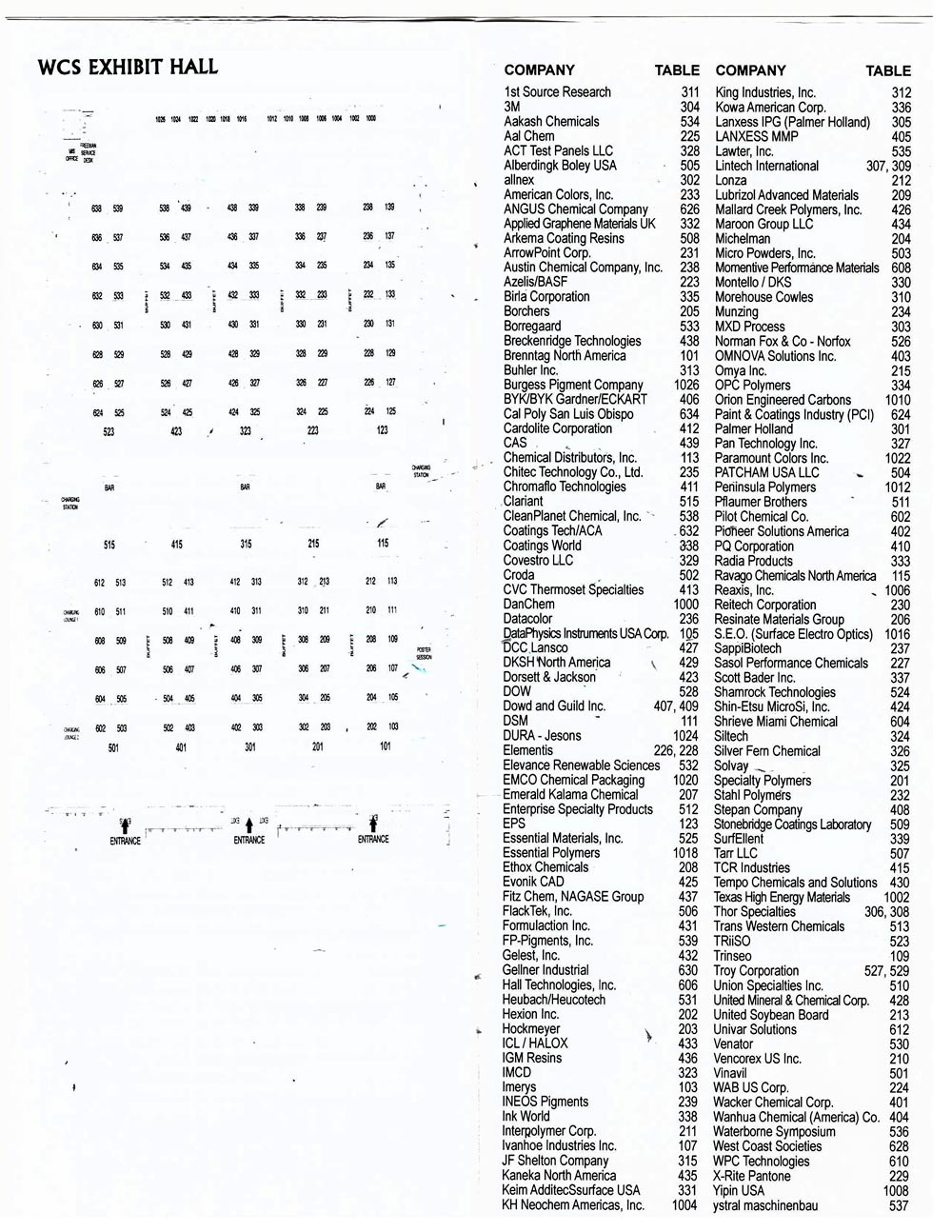

The show itself ran Sunday night through Wednesday afternoon. Kicking off with a cocktail party at Drai's on Sunday and finishing with an open bar after the last panelists on Wednesday afternoon. I was fortunate to have dinner plans with technical guys from BYK to discuss some questions I had regarding defoamers and surface leveling additives. Just about every meal of the week I had plans with either technical representatives from suppliers or different distributors we purchase raw materials from.

Overall I enjoyed the Western Coatings Show and I will probably attend again in 2021. This show is every other year, and in the meantime there is plenty to do working on formulations. The trade show hall was only open 2-3 hours a day on Monday and Tuesday, it was closed on the last day (Wednesday). I felt rushed trying to get around to all the different booths, but at least I stopped by booths with which we conduct business first. Out of the 100+ presentations I was able to sit through maybe 20 of them, and maybe half of those were interesting or relatable to what we actually do today.

Photos From The WCS 2019

Become a Slide-Lok Floor Coating & Cabinet Dealer

Open your contracting business to more opportunities with Slide-Lok. Slide-Lok is your one stop shop for garage flooring and storage solutions since 1977. Inquire today and discover the benefits of Slide-Lok Garage Interiors.

About The Author

Samuel Strayer is a trained chemist with a Bachelor of Science in Biochemistry from Arizona State University with an emphasis on material and polymer science. Samuel has been involved in developing and testing coating systems for over 10 years.

Keywords: western, coating, show, coatings, epoxy, polyurea, polyaspartic, mma, acrylic, wcs

© Copyright, 2019, Slide-Lok (DBA), Mirabel Coatings Inc.

Back to Posts on The Garage Makeover Blog

Contact Local Dealer

Find a Slide-Lok Garage Floor & Cabinet dealer in your area.

Call: 1-800-835-1759

E-mail: Click to e-mail.

Featured Blog Posts

- Concrete Coating System Adhesion Study

- We Want To Thank Our Suppliers!

- Closed July 2-5 for Independence Day

- Best Garage Floor Coatings in Phoenix, AZ

- New Flooring Chips and Flakes Brochure - Featuring 41 Colors!

- How To Choose The Right Color To Paint Your Garage

- 41 Stock Blends of Color Chips and Flakes for Floor Coatings

- 6 New Color Chips & Flakes for Floor Coatings

- Residential and Commercial Floor Coatings in Phoenix, Arizona

- 13 New Color Chips & Flakes for Floor Coatings

- 4 Home Improvement and Organizational Tips To Elevate Your Home

- Floor Coating Video

- Failed DIY Garage Floor Coating vs. Pro

- How To Get Smoother Top Coats, Chip and Flake Floor Coating Sealer

- Closed Labor Day Weekend Sept. 4-7

- Garage Floor Coating Transformation in Laramie, Wyoming

- Flooring Chips and Flakes Now Available By The Bucket

- Closed July 3-6 For Independence Day

- Fighting Allergies During COVID-19

- Become An Authorized Slide-Lok Floor Coating and Storage Installer

- Inventory Levels and Lead Times - Impacted Supply Chains

- Flooring Chips and Flakes Brochures

- Waterborne Epoxy Garage Floor Coating Training Video

- SBA Paycheck Protection Program - CARES ACT

- Spring Cleaning During Coronavirus Pandemic

- Staying Healthy: How To Minimize Your Risks Of Catching The Coronavirus (COVID-19)

- We Are Open, Taking & Shipping Orders

- When To Paint Your House - 5 Useful Tips For Interior Painting

- 10 Ideas For Your Garage Makeover

- Surviving WOC 2020: Coronavirus (COVID-19)

- The Best Time Of Year To Paint The Exterior Of Your Home

- Two Tone Chip Epoxy Floor in Mesa, Arizona

- Fitness Center Gets Metallic Epoxy Floor Coating

- Western Coating Societies Symposium and Show 2019

- Polyurea Is Better Than Polyaspartic?

- How To Improve Your Home's Curb Appeal

- 2 Tone Garage Floor Coating in Omaha, Nebraska

- Colorado Springs Garage Floor Restoration

- Polyaspartic Coating Survives as Boat Deck Coating

- Best Wasp & Hornet Pesticide Spray From Home Depot 2019

- Polyaspartic Flooring Withstands Flooding in Austin, Texas

- Garage Makeovers Shine in Florida

- Best Garage Remodels in Phoeniz, AZ

- Best Garage Makeovers of South Carolina

- Best Floor Coatings for Auto Mechanic Shops

- Garage Floor Coating Install in Anderson, IN

- DIY Epoxy Coating Repair in Casper, WY

- Polyaspartic Garage Floor Install in Pittsburgh, PA

- Garage Flooring & Painting in Omaha, Nebraska

- Concrete Coating Install in Eagan, Minnesota

- Garage Cabinet Installation in Wyoming, Michigan

- Garage Floor Coatings Albany, IN

Contact Local Dealer

Find a Slide-Lok Garage Floor & Cabinet dealer in your area.

Call: 1-800-835-1759

E-mail: Click to e-mail.

Featured Blog Posts

- Concrete Coating System Adhesion Study

- We Want To Thank Our Suppliers!

- Closed July 2-5 for Independence Day

- Best Garage Floor Coatings in Phoenix, AZ

- New Flooring Chips and Flakes Brochure - Featuring 41 Colors!

- How To Choose The Right Color To Paint Your Garage

- 41 Stock Blends of Color Chips and Flakes for Floor Coatings

- 6 New Color Chips & Flakes for Floor Coatings

- Residential and Commercial Floor Coatings in Phoenix, Arizona

- 13 New Color Chips & Flakes for Floor Coatings

- 4 Home Improvement and Organizational Tips To Elevate Your Home

- Floor Coating Video

- Failed DIY Garage Floor Coating vs. Pro

- How To Get Smoother Top Coats, Chip and Flake Floor Coating Sealer

- Closed Labor Day Weekend Sept. 4-7

- Garage Floor Coating Transformation in Laramie, Wyoming

- Flooring Chips and Flakes Now Available By The Bucket

- Closed July 3-6 For Independence Day

- Fighting Allergies During COVID-19

- Become An Authorized Slide-Lok Floor Coating and Storage Installer

- Inventory Levels and Lead Times - Impacted Supply Chains

- Flooring Chips and Flakes Brochures

- Waterborne Epoxy Garage Floor Coating Training Video

- SBA Paycheck Protection Program - CARES ACT

- Spring Cleaning During Coronavirus Pandemic

- Staying Healthy: How To Minimize Your Risks Of Catching The Coronavirus (COVID-19)

- We Are Open, Taking & Shipping Orders

- When To Paint Your House - 5 Useful Tips For Interior Painting

- 10 Ideas For Your Garage Makeover

- Surviving WOC 2020: Coronavirus (COVID-19)

- The Best Time Of Year To Paint The Exterior Of Your Home

- Two Tone Chip Epoxy Floor in Mesa, Arizona

- Fitness Center Gets Metallic Epoxy Floor Coating

- Western Coating Societies Symposium and Show 2019

- Polyurea Is Better Than Polyaspartic?

- How To Improve Your Home's Curb Appeal

- 2 Tone Garage Floor Coating in Omaha, Nebraska

- Colorado Springs Garage Floor Restoration

- Polyaspartic Coating Survives as Boat Deck Coating

- Best Wasp & Hornet Pesticide Spray From Home Depot 2019

- Polyaspartic Flooring Withstands Flooding in Austin, Texas

- Garage Makeovers Shine in Florida

- Best Garage Remodels in Phoeniz, AZ

- Best Garage Makeovers of South Carolina

- Best Floor Coatings for Auto Mechanic Shops

- Garage Floor Coating Install in Anderson, IN

- DIY Epoxy Coating Repair in Casper, WY

- Polyaspartic Garage Floor Install in Pittsburgh, PA

- Garage Flooring & Painting in Omaha, Nebraska

- Concrete Coating Install in Eagan, Minnesota

- Garage Cabinet Installation in Wyoming, Michigan

- Garage Floor Coatings Albany, IN